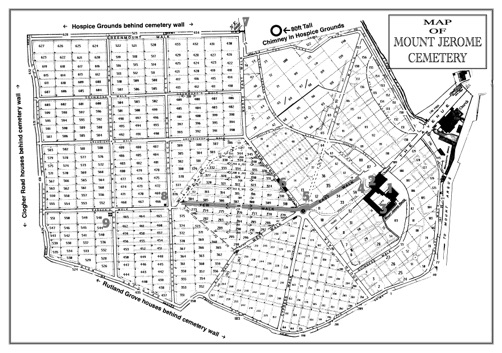

Mount Jerome was the first privately owned cemetery in Ireland, when it first opened in 1836. It was also the first privately owned crematorium in Ireland in 2000. To date we have received 220,000 funerals for burial and 25,000 for cremation. We receive 200,000 visitors annually.